At Snug Air, we believe in the power of preventative maintenance to keep your HVAC system running smoothly all year long. Regular maintenance isn’t just about preventing breakdowns—it’s about ensuring your system operates at peak efficiency, extending its lifespan, and saving you money on costly repairs. By having your system tuned up regularly, you’ll enjoy lower energy bills, improved air quality, and peace of mind knowing your home or business is always comfortable.

Introducing Snug Air’s Maintenance Plans – Comfort, Guaranteed

To make it easier for you to keep your HVAC system in top shape, we offer flexible, affordable maintenance plans designed to fit your needs. With our plans, you’ll receive:

Don’t wait for a breakdown — invest in a Snug Air maintenance plan today and enjoy hassle-free comfort year-round!

| Service Plan | Silver | Gold |

|---|---|---|

| Cost (First System) | $16.50/month | $34.00/month |

| Cost (Additional System) | $15.00/month | $30.00/month |

| Maintenance Visits | 2 per year | 2 per year |

| Repair Discount | 5% | 10% |

| Service Response Time | Priority | Priority |

| Service Call Fee | $100 | $80 |

| Reminder Service | Included | Included |

| Labor Repair Warranty | 1 year | 2 years |

| After-Hours Protection | Included | Included |

| Ductwork Inspection | Included | Included |

| New System Credit | Not included | 10% |

| Indoor Air Quality Assessment | Not included | Included |

Our HVAC Maintenance Checklists

Air Filter Assessment & Replacement – Inspect air filters for proper condition and airflow. We will replace any filter provided by the customer to maintain indoor air quality and system efficiency. (Snug Air does not stock or supply filters for maintenance services.)

Air Filter Assessment & Replacement – Inspect air filters for proper condition and airflow. We will replace any filter provided by the customer to maintain indoor air quality and system efficiency. (Snug Air does not stock or supply filters for maintenance services.)- Thermostat Operation – Check thermostat settings, calibration, and communication with the HVAC system to ensure accurate temperature control and response.

- Surveying Safety Controls – Inspect critical safety switches and devices to ensure the system is operating within safe parameters.

- Voltage and Amperage Measurements – Perform electrical diagnostics to confirm proper voltage and amperage levels, preventing premature component failure.

- Temperature Rise Measurements – Measure and analyze system temperature differentials to verify proper heat transfer and efficiency.

- Securing and Inspecting All Electrical Connections – Tighten and check electrical connections to prevent overheating, arcing, and potential system failures.

- Fine-Tuning the Refrigerant Charge (If Necessary) – Evaluate refrigerant levels using manufacturer specifications and adjust only if diagnostics indicate an issue requiring correction.

- Condensate Drain Inspection with Biocide Treatment (If Required) – Inspect and clear the condensate drain to prevent blockages, potential water damage, and microbial growth. Apply biocide treatment as needed.

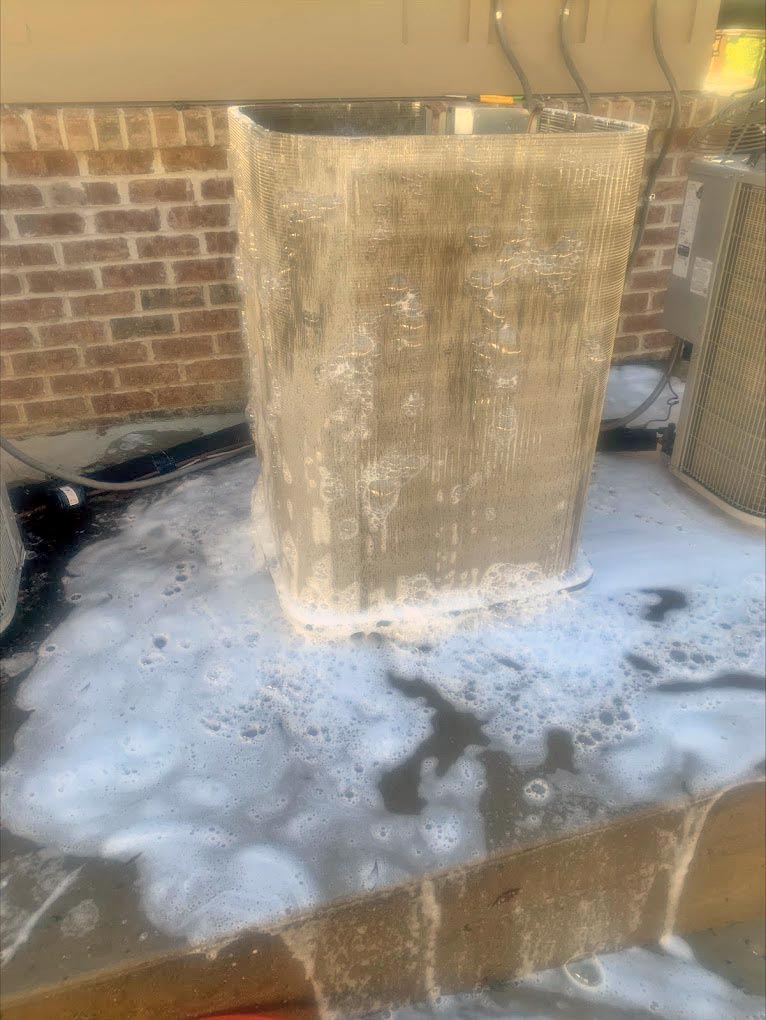

- Outdoor Coil Inspection & Cleaning – Inspect the outdoor coil for debris buildup. Perform a light Level-1 coil cleaning only if necessary, ensuring efficient system operation without unnecessary strain.

- Superheat and Subcooling Measurements – Verify superheat and subcooling values only if system diagnostics indicate a need for further assessment, preventing unnecessary gauge attachment and potential refrigerant contamination.

- Starting Relays and Contactors Checked – Test relays and contactors for proper function, ensuring reliable electrical operation.

- Cleaning Electrical Compartment – Remove dust, spider webs, or debris from the electrical compartment to maintain system integrity and prevent electrical issues.

- Indoor Blower Wheel Assessment – Evaluate blower wheel condition for efficiency and airflow performance. (Blower wheel cleaning is not included in routine maintenance, as excessive buildup is considered a system issue requiring corrective service.)

- Visual Indoor Coil Inspection & Surface Cleaning – Conduct a visual inspection of the indoor coil and perform surface cleaning only if the coil is easily accessible to ensure optimal heat exchange efficiency.

Thermostat Control & Response – We verify thermostat operation, settings, and response accuracy, ensuring proper communication between the thermostat and the heating system.

Thermostat Control & Response – We verify thermostat operation, settings, and response accuracy, ensuring proper communication between the thermostat and the heating system.- Filtration System & Air Quality – The filtration system is inspected, and we will replace any filter provided by the homeowner. Snug Air does not stock or supply filters as part of maintenance services.

- Heating Performance & Airflow Analysis – Heating performance is evaluated by measuring Delta T temperature rise for both primary and secondary heat isolation, ensuring efficient heat transfer. Airflow balance is checked to confirm proper distribution and comfort.

- Outdoor Coil Inspection & Cleaning – The outdoor coil is inspected, and a light Level-1 cleaning is performed if necessary, but only if the outdoor ambient temperature is above 40°F to prevent freezing or system inefficiencies.

- Indoor Coil Inspection & Surface Cleaning – The indoor coil is visually inspected, and surface cleaning is performed only if the coil is easily accessible.

- Blower System Performance – The blower motor is inspected for proper operation, and belts and pulleys, if applicable, are checked. The blower wheel is evaluated for dirt accumulation and airflow restrictions, though blower wheel cleaning is not included in routine maintenance, as excessive dirt buildup is considered a system issue requiring additional service.

- Electrical Component Testing & Safety Checks – We test and inspect starting relays and contactors, capacitors for proper tolerances, and safety switches. Secondary heat components, such as heat strips, are also tested along with their controlling relays or sequencers.

- Heat Pump & Defrost System Testing – If the system includes a heat pump, we test the defrost operations to ensure proper engagement and disengagement during winter operation.

- System Integrity & Final Checks – Electrical compartments are cleaned of dust, spider webs, or debris. We verify that all refrigeration service caps are present and properly torqued to prevent leaks and contamination, replacing missing or damaged service caps as needed.

- Thermostat Performance & System Calibration – We inspect and test your thermostat to ensure precise temperature control and efficient heating response. Proper calibration ensures your system is running optimally without unnecessary energy waste.

- Filter Inspection & Replacement – A clean filter is essential for proper airflow and efficiency. We inspect the filter system and replace customer-provided filters as needed. (Snug Air does not supply filters as part of maintenance services.)

- Furnace Ignition & Burn Cycle Evaluation – We assess the ignition process and burner operation to confirm smooth and efficient system startup. This ensures that gas combustion is occurring safely and effectively.

- Draft Inducer System & Venting Inspection – The draft inducer motor and venting system are checked for proper airflow, amperage draw, and obstructions that could affect efficiency and safety.

- Flame Sensor Cleaning & Reliability Testing – The flame sensor is cleaned and tested to verify strong ignition signals, reducing the risk of startup failures.

- Heat Exchanger & Burner Condition Check – A cracked or damaged heat exchanger can lead to serious safety hazards. We inspect accessible areas for cracks, rust, or corrosion. Burners are also examined for even flame distribution and smooth crossover ignition.

- Heating Output & Airflow Assessment – Proper heat distribution is key to comfort. We measure temperature rise (Delta T) and airflow to ensure your system is producing the right amount of heat and delivering it effectively throughout your home.

- Safety Controls & Limit Switch Verification – All safety switches, including high-limit and rollout switches, are tested to ensure the system shuts down properly in case of an issue, preventing overheating and unsafe conditions.

- Electrical Component & Connection Inspection – We inspect relays, contactors, and capacitor tolerances, ensuring electrical connections are secure and components are operating correctly. Any loose or failing parts are noted for corrective action.

- Blower Motor & Fan System Check – The blower motor is tested for proper operation, and belts (if applicable) are inspected for wear or slack. The blower wheel is evaluated for dirt buildup, as restricted airflow can reduce efficiency and strain the system. (Blower wheel cleaning is not included in routine maintenance, as excessive buildup is considered a system issue requiring corrective service.)

- Condensate Drain & Trap Cleaning (For High-Efficiency Furnaces) – High-efficiency furnaces generate condensation that must be properly drained. We inspect the condensate system, clean the drain line if necessary, and check the collector box for potential blockages.

- Burner & Electrical Compartment Cleaning – Dirt, dust, and debris in the burner compartment can lead to efficiency loss and safety risks. We clean and clear any obstructions from this area, ensuring smooth system operation.

- Final System Check & Performance Optimization – Before finishing, we conduct a final assessment of overall system function, ensuring your furnace is operating efficiently, safely, and reliably before the colder months set in.

Book online now, or call us today.